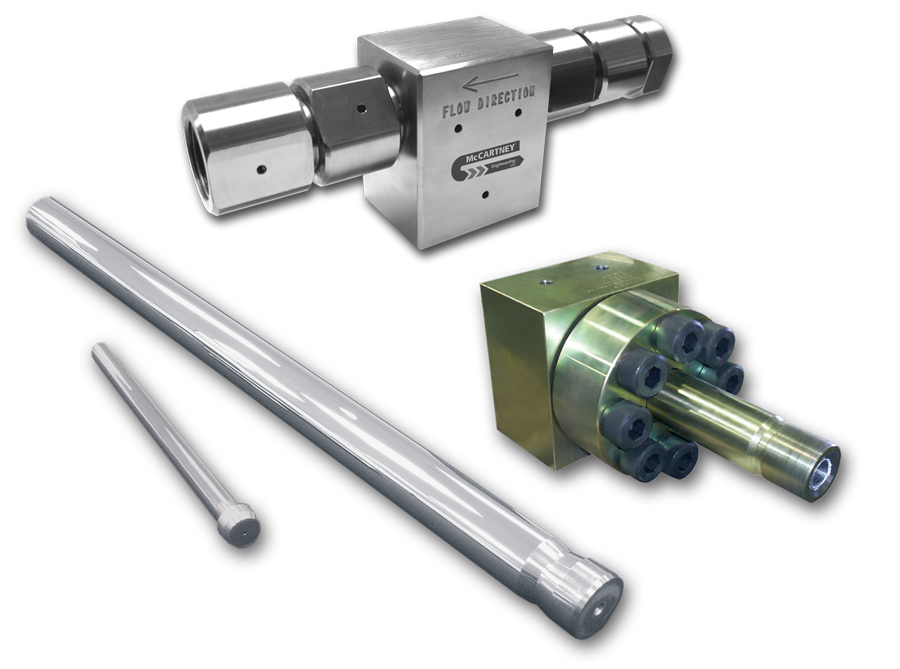

McCARTNEY PMH PUMP

McCARTNEY PMH SINGLE & DUAL PEROXIDE INJECTION PUMPS

The McCartney PMH hydraulic-driven reciprocating metering pump has long been the industry workhorse for initiator injection.

The McCartney PMH Pump, now available with Single or Dual Intensifiers, is the latest generation of reciprocating peroxide injection LDPE pumps.

The PMH pump includes the newest proven designs for the intensifier top works as well as the hydraulic drive unit. These pumps are equipped with state of the art electronic controls, replacing the now obsolete pneumatic controls used for many years. This new electronic control system can be programmed to suit any specific process, providing precision control of initiator flow and reactor temperature.

- Pump units are available in single configuration or in a dual configuration when space is a consideration.

- Single and dual pump units are supplied with manifolded process suction and discharge piping with single point connections.

- Check valve cooling jackets are an option when initiator flashing is a concern.

- High pressure cylinder cooling jackets are standard.

Estimated Service Life:

The estimated service life for the following components is based on customer supplied historical data, and cannot be guaranteed.

- Plunger………………………………………3-4 years

- High Pressure Seal…………………4,000-18,000 hrs.

- Check Valve………………………………7,500 hrs.

- High Pressure Cylinder…………2-5 years

- Hydraulic Cylinder Seals……….2-4 years

- Hydraulic Piston Rings………….7-10 years

- Hydraulic Pump………………………7-10 years

PMH Pump Features & Benefits:

- PMH Topworks Upgrade Available for Older Pumps

- Hydraulic Driven

Reciprocating Metering Pump with

Reciprocating Metering Pump with

Electronic Control - Initiator Injection: 1380 – 4100 bar

- Modifier Injection: 345 – 600 bar

- Proven Reliability for More than 45 Years

- Extended Check Valve and Packing Lifetime

- Easy Access Door and Panel Enclosure

- 3-Piece Elastomer Plunger Seal

- Stainless Steel Cylinder and Check Valve Body

- Magnetic Proximity Reversing Devices

- High Pressure Seal Lubricator

- Continuous Hydraulic Fluid Recirculation for Filtration

and Cooling - Epoxy Powder Coated 170L (45 Gal) Hydraulic Oil Reservoir, Stainless Steel is Optional

- Axial Piston Hydraulic Pump

- HP Cylinder Cooling Jackets